‘PALI Group is actively involved in the entire chain, from purchasing the animals to selling the meat, and everything in between.’

Onno Hidding, Livestock division manager

Partner in livestock Calves, pigs and goats

Livestock farmers, traders, and abattoirs can rely on PALI Group. We ensure a perfect match between supply and demand.

Our veal chain

PALI Group is globally recognised as a producer of premium veal products. Our added value lies in our partnerships with suppliers, veal farmers, traders and customers. We ensure the veal farmers have dedicated contacts to guide them in the purchase and sales process so that supply and demand are perfectly matched. We also provide support, devise feed schedules if required and handle identification and registration paperwork. Furthermore, we handle the transport, slaughter and processing of veal.

We maintain control throughout this chain, with a focus on quality and respect for people, animals and the environment. Together with our chain partners, we ensure optimal conditions and excellent end results.

Calf purchasing

We purchase unweaned calves on a daily basis. After a strict selection process, we sell them on to veal farms or place them with affiliated veal farmers, who ensure the animals are raised in the best possible conditions.

Veal farming

Our calves are raised on certified veal farms. Some of these farms are owned by us, while others work with us under contract. Independent veal farms can also rely on us for support.

Transport

We largely handle the transport of calves and veal products ourselves with our fleet of specially equipped livestock trucks and a team of dedicated drivers. PALI Logistics manages all aspects of the transport process.

Our veal abattoir

PALI Group has its own professional veal abattoir, Vitelco, in 's-Hertogenbosch. This facility operates year-round. Our skilled professionals process around 250,000 animals annually with respect and precision.

Our deboning hall

In addition to the abattoir, PALI Group also has its own veal deboning hall in 's-Hertogenbosch. Here, we process the calves into bone-in and boneless veal products within a day of slaughter.

Our cold store

Our cold storage facility in 's-Hertogenbosch has a storage capacity of 45,000 square metres and a freezing capacity of 150 tonnes of meat per day. Freezing takes place immediately after the animal is slaughtered or the meat is processed. Our customers can specify the method used, either tunnel freezing or plate freezing. Products are frozen at very high speed, guaranteeing the meat's quality.

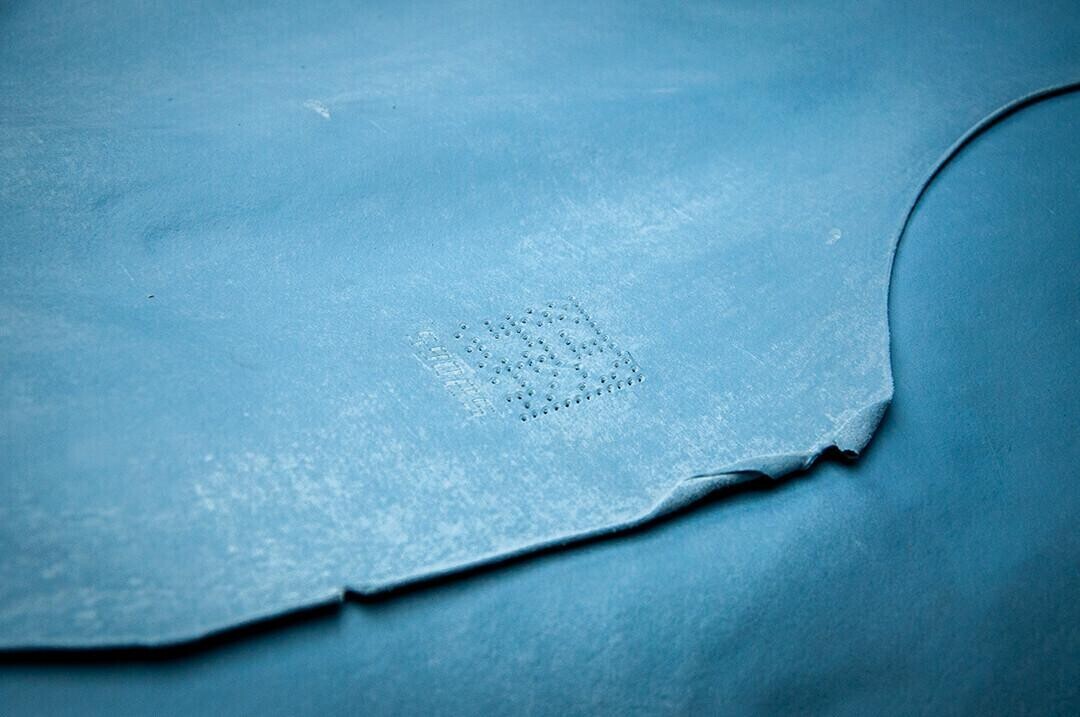

Our hides

Calf hides and skins are by-products of the slaughter process. All hides are sent to our subsidiary Bohide, where they are trimmed, sorted, chilled and, if necessary, salted. They are then marketed in various forms by Vitelco Leather.

Veal sales

Our veal products find their way to customers around the world via Vitelco, part of PALI Group. We sell the meat according to our customers' preferences: in large volumes, in a variety of cuts, portioned or ready-to-use.

PALI Group calves in numbers

Our activities in veal production yield results that we are proud of. These are made possible by the strength of our collaboration with our partners in the supply chain, our skilled and dedicated employees, and our ambition to supply premium veal products in a responsible way.

75

contracted veal farms12

veal farm specialists20

livestock trucks5,000

slaughters a week